SERVICIILE CITYPLAY:

Garantie pana la 25 de ani

Materiale de calitate superioara

Proiectare 3D si Consultanta Gratuite

Peste 300 de parcuri de joaca executate

- Preturile afisate pe site sunt negociabile in functie de complexitatea proiectului dumneavoastra si numarul si tipul echipamentelor comandate.

- In urma achizitionarii echipamentului veti primi in plus consultanta pe tot parcursul proiectului, instalarea echipamentului si transportul acestuia pana la locatie. Dupa finalizarea proiectului veti beneficia de serviciile noastre de mentenanta in baza garantiei, oricand va fi necesar.

- Daca optati sa achizitionati echipamentele CityPlay pentru realizarea unui proiect complet, care va include o gama diversificata de echipamente, ne puteti contacta pentru o oferta personalizata sau puteti completa direct online formularul nostru dedicat ofertarii personalizate.

- Produsele incarcate pe website sunt de prezentare, ele reprezinta o selectie de echipamente pe care le-am ales in urma unei analize generale a preferintelor clientilor nostrii. Gama noastra de produse furnizate este mult mai diversificata si cuprinde si alte echipamente ce ar putea fi integrate in proiectul tau. Asadar, in cazul in care nu ati identificat inca echipamentul potrivit, nu ezitati sa ne contactati pentru a ne oferi mai multe detalii, ca noi sa va putem oferi solutia potrivita pentru dumneavoastra.

- Preturile nu sunt publicate pe site pentru toate produsele afisate intrucat avem disponibilitatea de a le personaliza in functie de complexitatea proiectului dumneavoastra.

- Descriere

- Fisa Tehnica

- Garantii si Certificate

- Livrare Si Montaj

- Review-uri (0)

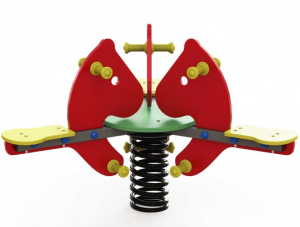

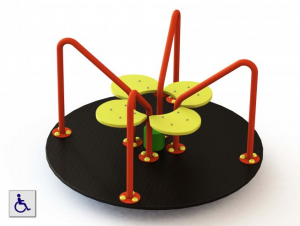

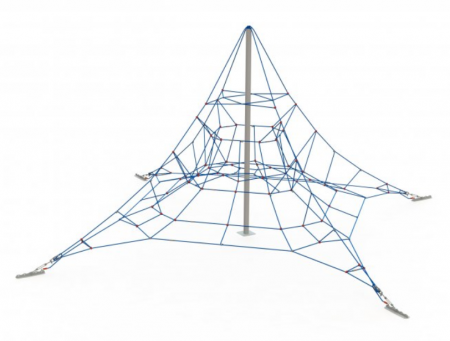

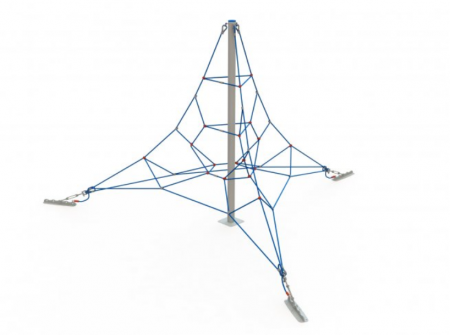

| Nume produs | Ansamblu de joaca multifunctional Padure |

| Cod produs | CJ-801 |

| Activitati | urcare, alunecare, socializare, catarare, jocuri interactive si educationale, leganare, echilibru, coordonare |

| Interval de varsta | 3-12 ani |

| Numar de locuri | 12+ locuri |

| Inaltimea maxima de cadere | 1.250 mm |

| Structura de baza | tevi de metal |

| Materiale principale utilizate | HDPE, PVC Forex, HEXA |

| Dimensiunile echipamentului | 8.963 x 11.932 mm |

| Suprafata de siguranta | 12.963 x 15.432 mm |

| Suprafete permise | iarba, nisip, pelete de lemn, suprafață de cauciuc care atenuează loviturile – 2mp |

Център за Изпитване и

Европейска Сертификация

ISO 9001:2008

Сертификат № 0008/24.03.2010г. ISO 14001:2004

Сертификат № 0145/15.09.2015г. BS OHSAS 18001:2007

Сертификат № 0146/15.09.2015г.

TECHNICAL SPECIFICATION of equipment for children playground CJ-801 Children play unit Jumbo serie

COZIROG - D LTD

e-mail: info@cozirog.com

www.cozirog.com

Dimensions of the equipment CJ-801

Safety area dimensions of the equipment

CJ-801 - 120,50 m2

COZIROG - D LTD

e-mail: info@cozirog.com

www.cozirog.com

Age range: from 0 to 3 / from 3 to 12 years

The equipment offers the following components for play: climbing / sliding/ balance / educational / crawling / communication / teamgames / experimentation / coordination / orientation / inserting

Maximum fall height: 1 250 mm

Height of the platforms: 90, 160, 330, 590, 980, 1250 mm

Equipment dimensions: 8 963 х 11 932 mm

Warranty term: 60 months

Safety area dimensions: 11 963 х 15 432 mm

Admissible surfaces: sand, wood chips, rubber impact absorbing flooring - 2 sm The equipment meets the requirements of:

- Regulation №1 from January 12, 2009 about the conditions and order for organization and safety of playgrounds

- EN 1176-1 Playground equipment standard Part 1: General safety requirements and test methods

- EN 1176-3 Playground equipment standard Part 3: Additional specific safety requirements and test methods for slides

- EN 1176-11 Playground equipment standard Part 11: Additional specific safety requirements and test methods for spatial network

Compulsory parental control of children up to 3 years!

Usage of the equipment is prohibited in cases where the installation on site is not completed, or during disassembly and repair works!

Design

COZIROG - D play units and products are designed and tested so as to ensure maximum fun and safety of children using them. In the design process of the playgrounds, the team is aware that there are enormous requirements on him - from budgetary constraints to individual opportunities and limitations that each site has; from the initial concept to final performance - everything is taken into account.

EN 1176 certification

Safety of children using the play equipment is fundamental importance and therefor all of our sites are strictly tested according to the highest European standards. So that you can be sure that play unit is safe while children spend his best moments.

ISO 9001:2008

Upholding typical quality COZIROG - D possess quality management system, which ensures the use of only the high quality raw materials in the manufacture of play equipment and products which aims final product to meet the highest standards.

COZIROG - D LTD

e-mail: info@cozirog.com

www.cozirog.com

Painting

Equipment designed for outdoors installation and sports equipment are subject to environmental influences for a long time. The way of painting so as to increase the life of the product and to avoid corrosion is a very important process. The metal equipment is initially cleaned in order to remove all the shortcomings of steel. Then it is primed, which serves to smooth the surface and is basis for the final painting. Main stucture

For structural elements of children playground Jumbo series metal profiles 60X60 thickness 2 mm are used. Platforms are made of the same profile by means of bolts or welding to the main columns.

Platforms and domes

The platforms are made by high-quality waterproof plywood НЕХА, domes are made by high quality plastic. They are fastened by screws for pre-welded profiles to the main structure.

Ladders and climbing frames

Ladders and climbing frames are produced by using of metal profiles or tubes with the necessary size and strength. For making rope ladders steel - cored wire rope is used. Slides

Slides are made of multilayer fiberglass. Fiberglass is resistant to UV rays with adequate strength for exploitation of children in the specified age range. Slides are smooth, easy to clean and have no sharp edges and bulges. Slides are tested and have test protocol issued by licensed laboratory for compliance with the requirements of BDS 71-3 (Safety of toys - migration of certain elements).

Stairs, fences, decorative items

These elements are made of: fences - ; decorative

elements - high quality plastic; stairs - colored polyethylene; for climbing frames rocks, rubber pads and handles of colored polyethylene.

MAINTENANCE AND CONTROL OF EQUIPMENT a) Routine visual inspection

Routine visual inspection is done by the owner of the site and gives the opportunity to find out the obvious hazards that may be result of vandalism, use or weather conditions. For sites where the facilities are subject of use with increased load or vandalism is required daily control of this type. The visual inspection includes: the cleanliness of the facility, cleaning the terrain around the facility, surface finish, exposure of the foundation, sharp edges, missing parts, excessive wear and constructive integrity, maintaining the level of the sand to mark sign.

COZIROG - D LTD

e-mail: info@cozirog.com

www.cozirog.com

b) Functional control

Functional control is more detailed tests to check the functioning and stability of the facility, in particular for any wearing out. It has to be performed every 1 to 3 months from the owner of the site or authorized person.

Inspection scope includes:

- Chipping or other violations of surfaces;

- Corrosion of metal parts;

- Rough surfaces which could be a risk of injury as well as jutting out heads of bolts or nuts;

- Whether all corners, edges and protruding parts are rounded; - If all joints are aligned to the base;

- Lack of caps on the ends of open pipes;

- Detachable connections;

- Protruding parts above the ground foundations;

- Corrosion and rot the foundations of facilities;

c) Annual main control

The annual basic controls is carried out to establish for the interval of 10 to 12 months, the overall level of safety of the facility, foundations and surfaces, such as the effects of weather, obviously rotting or corrosion and any changes in the level of safety of the equipment as a result of repairs made or added or replaced component. NOTE: Annual main control may require disclosure/excavation or disman tling of certain parts.

This control should be done by competent persons.

![echipamente-de-joaca-ansamblu-de-joaca-multifunctional-pentru-copii-3-12-ani [0] echipamente-de-joaca-ansamblu-de-joaca-multifunctional-pentru-copii-3-12-ani [0]](https://gomagcdn.ro/domains/cityplay.ro/files/product/medium/ansamblu-de-joaca-multifunctional-padure-cj-801-jumbo-3-12-ani-888893.jpg)

![echipamente-de-joaca-ansamblu-de-joaca-multifunctional-pentru-copii-3-12-ani [1] echipamente-de-joaca-ansamblu-de-joaca-multifunctional-pentru-copii-3-12-ani [1]](https://gomagcdn.ro/domains/cityplay.ro/files/product/medium/ansamblu-de-joaca-multifunctional-padure-cj-801-jumbo-3-12-ani-884035.jpg)

![echipamente-de-joaca-ansamblu-de-joaca-multifunctional-pentru-copii-3-12-ani [2] echipamente-de-joaca-ansamblu-de-joaca-multifunctional-pentru-copii-3-12-ani [2]](https://gomagcdn.ro/domains/cityplay.ro/files/product/medium/ansamblu-de-joaca-multifunctional-padure-cj-801-jumbo-3-12-ani-473671.jpg)

![echipamente-de-joaca-ansamblu-de-joaca-multifunctional-pentru-copii-3-12-ani [3] echipamente-de-joaca-ansamblu-de-joaca-multifunctional-pentru-copii-3-12-ani [3]](https://gomagcdn.ro/domains/cityplay.ro/files/product/medium/ansamblu-de-joaca-multifunctional-padure-cj-801-jumbo-3-12-ani-016878.jpg)

![echipamente-de-joaca-ansamblu-de-joaca-multifunctional-pentru-copii-3-12-ani [4] echipamente-de-joaca-ansamblu-de-joaca-multifunctional-pentru-copii-3-12-ani [4]](https://gomagcdn.ro/domains/cityplay.ro/files/product/medium/ansamblu-de-joaca-multifunctional-padure-cj-801-jumbo-3-12-ani-738423.jpg)

![echipamente-de-joaca-ansamblu-de-joaca-multifunctional-pentru-copii-3-12-ani [5] echipamente-de-joaca-ansamblu-de-joaca-multifunctional-pentru-copii-3-12-ani [5]](https://gomagcdn.ro/domains/cityplay.ro/files/product/medium/ansamblu-de-joaca-multifunctional-padure-cj-801-jumbo-3-12-ani-958581.jpg)

![echipamente-de-joaca-ansamblu-de-joaca-multifunctional-pentru-copii-3-12-ani [1] echipamente-de-joaca-ansamblu-de-joaca-multifunctional-pentru-copii-3-12-ani [1]](https://gomagcdn.ro/domains/cityplay.ro/files/product/large/ansamblu-de-joaca-multifunctional-padure-cj-801-jumbo-3-12-ani-888893.jpg)

![echipamente-de-joaca-ansamblu-de-joaca-multifunctional-pentru-copii-3-12-ani [2] echipamente-de-joaca-ansamblu-de-joaca-multifunctional-pentru-copii-3-12-ani [2]](https://gomagcdn.ro/domains/cityplay.ro/files/product/large/ansamblu-de-joaca-multifunctional-padure-cj-801-jumbo-3-12-ani-884035.jpg)

![echipamente-de-joaca-ansamblu-de-joaca-multifunctional-pentru-copii-3-12-ani [3] echipamente-de-joaca-ansamblu-de-joaca-multifunctional-pentru-copii-3-12-ani [3]](https://gomagcdn.ro/domains/cityplay.ro/files/product/large/ansamblu-de-joaca-multifunctional-padure-cj-801-jumbo-3-12-ani-473671.jpg)

![echipamente-de-joaca-ansamblu-de-joaca-multifunctional-pentru-copii-3-12-ani [4] echipamente-de-joaca-ansamblu-de-joaca-multifunctional-pentru-copii-3-12-ani [4]](https://gomagcdn.ro/domains/cityplay.ro/files/product/large/ansamblu-de-joaca-multifunctional-padure-cj-801-jumbo-3-12-ani-016878.jpg)

![echipamente-de-joaca-ansamblu-de-joaca-multifunctional-pentru-copii-3-12-ani [5] echipamente-de-joaca-ansamblu-de-joaca-multifunctional-pentru-copii-3-12-ani [5]](https://gomagcdn.ro/domains/cityplay.ro/files/product/large/ansamblu-de-joaca-multifunctional-padure-cj-801-jumbo-3-12-ani-738423.jpg)

![echipamente-de-joaca-ansamblu-de-joaca-multifunctional-pentru-copii-3-12-ani [6] echipamente-de-joaca-ansamblu-de-joaca-multifunctional-pentru-copii-3-12-ani [6]](https://gomagcdn.ro/domains/cityplay.ro/files/product/large/ansamblu-de-joaca-multifunctional-padure-cj-801-jumbo-3-12-ani-958581.jpg)